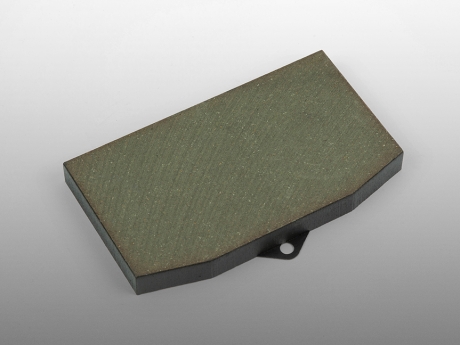

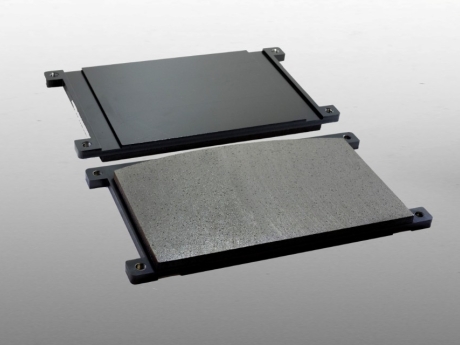

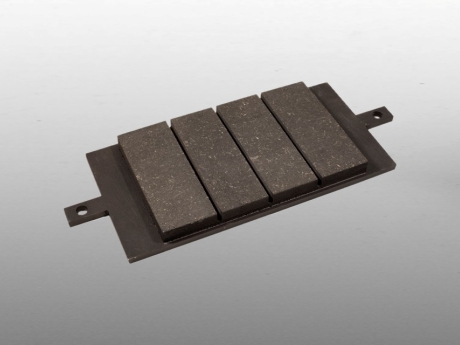

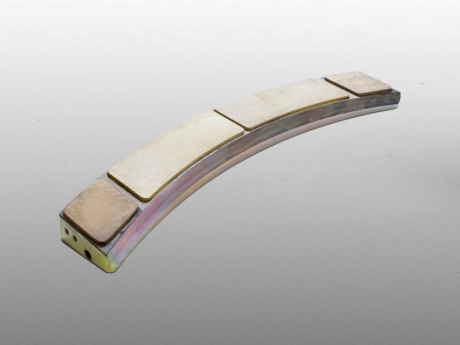

Brake Pads

Early back in the 1990's we began to produce brake pads for some industrial appliances. Since then, over the years we have gradually improved many different aspects with these products and have expanded our market range.

After developing a very high standard for the bonding procedure, we could guarantee a perfect adhesion between the lining and the steel-backing plate. Today we produce thousands weekly.

| NAME | STATIC COEF. (U) | DYNAMIC COEF. (U) | T FADING (ºC) | WEAR RATE (mm3KWH) | COMPRESSIVE STRENGTH (MPa) | |

|---|---|---|---|---|---|---|

| MM-MEX | 0.47±0.05 | 0.40±0.05 | >250 | 25 (at 150 ºC) | 361±5 | |

| FAG18/15 | 0.45±0.05 | 0.52±0.05 | >450 | 30 (at 150 ºC) | 160±5 | |

| G95 | 0.60±0.05 | 0.55±0.05 | >300 | 25 (at 150 ºC) | 120±5 | |

| FAG/M | 0.52±0.05 | 0.47±0.05 | >350 | 30 (at 150 ºC) | 160±5 | |

| GHFM | 0.50±0.05 | 0.50±0.05 | >350 | 30 (at 150 ºC) | 190±5 | |

| FAG/TW | 0.50±0.05 | 0.47±0.05 | >350 | 20 (at 150 ºC) | 170±5 | |

| SFD | 0.50±0.05 | 0.40±0.05 | >310 | 60 (at 150 ºC) | 115±10 | |

| SF-MC2 | 0.45±0.05 | 0.40±0.05 | >400 | 30 (at 150 ºC) | 306±10 | |

| MC140 | 0.65±0.05 | 0.63±0.05 | >550 | 50 (at 150 ºC) | 125±10 | |

| SA80/25 | 0.35±0.05 | 0.28±0.05 | >250 | 15 (at 150 ºC) | 100±5 | |

| SA65 | 0.60±0.05 | 0.65±0.05 | >350 | 45 (at 150 ºC) | 180±5 | |

| MC3 | 0.65±0.05 | 0.62±0.05 | >400 | 40 (at 150 ºC) | 126±5 | |

| CR-2M | 0.40±0.05 | 0.45±0.05 | >350 | 20 (at 150 ºC) | 126±5 | |

| RP01 | 0.50±0.05 | 0.40±0.05 | >310 | 60 (at 150 ºC) | 110±5 |

PRODUCTS UNDER REQUEST / We produce all sort of parts according drawings or samples