INDUSTRIAL PARTS

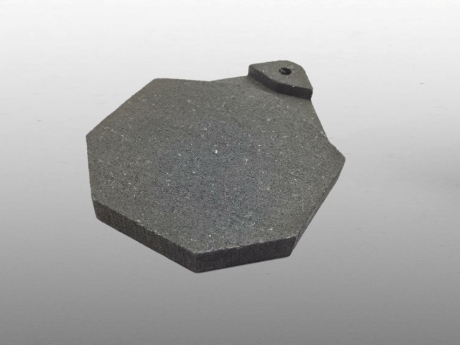

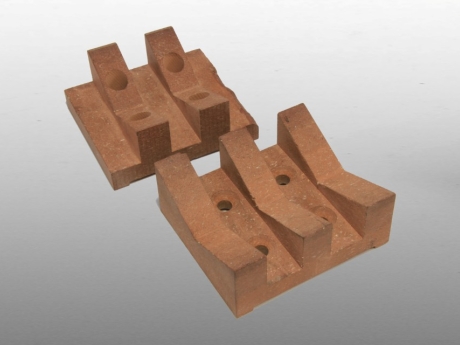

All items not included in the previous field of products could be classified as general industrial applications.

From CNC machined items with rather complicated shapes or radius to thinner and simpler parts cut on our water-jet machinery, such as sectors, shims, and even customized pieces for any kind of machine, we can produce whichever model imaginable.

| NAME | STATIC COEF. (U) | DYNAMIC COEF. (U) | T FADING (ºC) | WEAR RATE (mm3KWH) | COMPRESSIVE STRENGTH (MPa) | |

|---|---|---|---|---|---|---|

| MM-MEX | 0.47±0.05 | 0.40±0.05 | >250 | 25 (at 150 ºC) | 361±5 | |

| FAG18/15 | 0.45±0.05 | 0.52±0.05 | >450 | 30 (at 150 ºC) | 160±5 | |

| G95 | 0.60±0.05 | 0.55±0.05 | >300 | 25 (at 150 ºC) | 120±5 | |

| SA80/M | 0.60±0.05 | 0.50±0.05 | >340 | 60 (at 150 ºC) | 100±5 | |

| SA80/10 | 0.46±0.05 | 0.48±0.05 | >350 | 25 (at 150 ºC) | 104±5 | |

| SA80/20 | 0.42±0.05 | 0.35±0.05 | >350 | 25 (at 150 ºC) | 83±5 | |

| SAFF | 0.55±0.05 | 0.60±0.05 | >350 | 25 (at 150 ºC) | 175±5 | |

| SA80/05 | 0.60±0.05 | 0.57±0.05 | >350 | 80 (at 150 ºC) | 102±5 | |

| FAG/M | 0.52±0.05 | 0.47±0.05 | >350 | 30 (at 150 ºC) | 160±5 | |

| GHFM | 0.50±0.05 | 0.50±0.05 | >350 | 30 (at 150 ºC) | 190±5 | |

| NT-DV | 0.59±0.05 | 0.50±0.05 | >350 | 25 (at 150 ºC) | 175±5 | |

| HDS57 | 0.53±0.05 | 0.50±0.05 | >350 | 30 (at 150 ºC) | 120±5 | |

| HCC | 0.45±0.05 | 0.45±0.05 | >400 | 35 (at 150 ºC) | 140±5 | |

| SA92 | 0.53±0.05 | 0.40±0.05 | >350 | 50 (at 150 ºC) | 150±5 | |

| MM | 0.50±0.05 | 0.30±0.05 | >200 | 40 (at 150 ºC) | 410±5 | |

| NR | 0.53±0.05 | 0.40±0.05 | >350 | 50 (at 150 ºC) | 150±5 | |

| SFD | 0.50±0.05 | 0.40±0.05 | >310 | 60 (at 150 ºC) | 115±10 | |

| SF-BU | 0.43±0.05 | 0.35±0.05 | >400 | 30 (at 150 ºC) | 306±10 | |

| MC140 | 0.65±0.05 | 0.63±0.05 | >550 | 50 (at 150 ºC) | 125±10 | |

| ST-06 | 0.43±0.05 | 0.40±0.05 | >350 | 40 (at 150 ºC) | 120±5 | |

| SA65 | 0.60±0.05 | 0.65±0.05 | >350 | 45 (at 150 ºC) | 180±5 | |

| MC3 | 0.65±0.05 | 0.62±0.05 | >400 | 40 (at 150 ºC) | 126±5 | |

| CR-2M | 0.40±0.05 | 0.45±0.05 | >350 | 20 (at 150 ºC) | 126±5 | |

| TOP/05 | 0.60±0.05 | 0.50±0.05 | >300 | 40 (at 150 ºC) | 143±5 |