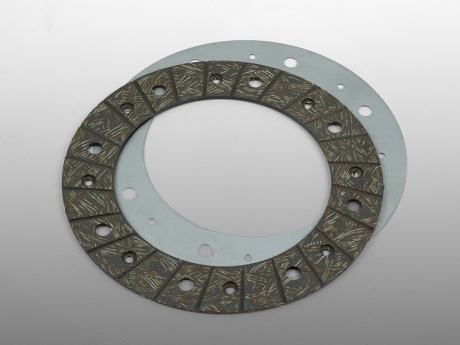

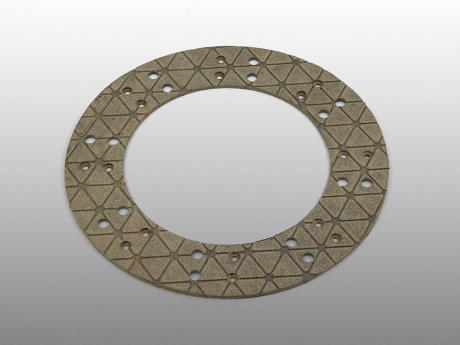

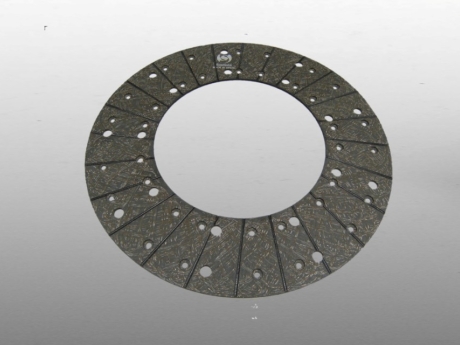

CLUTCH FACINGS

Clutch facings have been our principle basic business since we began manufacturing back in 1953. Over these years diffent formulations have been developed to cover the demand from all sectors improving them over the years. In time we reached a very high standard and were finaly approved by the OE of clutch manufacturing. There are special qualities for almost any kind of vehicle, from standard small cars, to heavy-duty vehicles, tractors, trucks and many kinds of racing cars.

Materials

| NAME | STATIC COEF. (U) | DYNAMIC COEF. (U) | T FADING (ºC) | WEAR RATE (mm3KWH) | COMPRESSIVE STRENGTH (MPa) | |

|---|---|---|---|---|---|---|

| G95 | 0.60±0.05 | 0.55±0.05 | >300 | 25 (at 150 ºC) | 120±5 | |

| JTC | 0.45±0.05 | 0.40±0.05 | >400 | 35( at 150ºC) | 145±5 | |

| HDS57 | 0.53±0.05 | 0.50±0.05 | >350 | 30 (at 150 ºC) | 120±5 | |

| HCC | 0.45±0.05 | 0.45±0.05 | >400 | 35 (at 150 ºC) | 140±5 | |

| SF-MC2 | 0.45±0.05 | 0.40±0.05 | >400 | 30 (at 150 ºC) | 306±10 | |

| SF-2SB | 0.65±0.05 | 0.70±0.05 | >500 | 60 (at 150 ºC) | 300±10 | |

| VH-03 | 0.44±0.05 | 0.38±0.05 | >350 | 30 (at 150 ºC) | 120±5 |

PRODUCTS UNDER REQUEST / We produce all sort of parts according drawings or samples